The Top 5 Myths about Steel Buildings

The Truth Behind the Myths

Steel buildings have evolved far beyond the bare-bones warehouses of decades past. Today, builders use them for everything from sleek retail centers to high-tech data storage and creative workspaces. Yet despite their growing popularity, many myths still surround steel construction.

Maybe you’ve heard that steel buildings feel cold, look unattractive, or only suit industrial spaces. These common misconceptions often cause people to overlook one of the smartest and most versatile building options available.

Let’s bust the top 5 myths about steel buildings—and uncover the truth behind each one.

Myth #1: Steel Buildings Are Ugly and Plain

The Truth:

Modern steel structures break away from the dull designs of the past. With today’s design options, you can create a structure that truly stands out. Decorative facades, architectural trim, vibrant colors, and custom rooflines allow you to tailor a steel building to match your brand, style, or function.

Many people feel surprised when they find out that a trendy coffee shop or boutique store is actually a pre-engineered steel building with a modern finish.

Pro tip: Decorative wraps, diverse siding cladding, wrap around porches and so much more can be added to blend with urban or rural environments while keeping the structural benefits of steel underneath.

Myth #2: Steel framed structures Are Only for Industrial Use

The Truth: While engineered steel buildings are popular in warehouses and factories, their applications go far beyond that. Entrepreneurs, churches, schools, municipalities, and even homeowners are embracing steel for a wide range of uses.

Steel today is used for:

• Retail centers

• Office parks

• Mini storage developments

• Agricultural barns

• Gyms and fitness centers

• Hobby sheds and creative studios

The flexibility of steel means you can design your space your way—without the limitations of traditional construction.

Myth #3: Steel Doesn’t Hold Up in Bad Weather

The Truth: Steel is one of the most durable construction materials available. When properly engineered and anchored, steel buildings are designed to handle:

Metal roof over wood framing being peeled back due to high winds.

High winds Thanks to the strength and flexibility of steel, these buildings resist high winds including those over 120 mph. Steel structures handle the intense pressure that wind places on walls, roofs, and foundations. High winds create uplift forces, especially on the roof, which can lift or tear it off if not properly secured. In critical wind zones, builders reinforce connections and use heavy-duty fasteners to hold the structure together. They also focus on securely fastening roof panels and applying advanced framing techniques to prevent roof roll-back. These measures help the building stay intact and stable under extreme wind pressure, protecting its overall integrity.

Heavy snow loads: - Engineered steel buildings handle heavy snow loads and ice damming with ease. Snow places strong downward pressure on the roof, and when melting snow refreezes at the eaves, ice damming can cause damage or leaks. To prevent this, builders in snow-heavy regions use reinforced beams and design sloped roofs to shed snow effectively. Proper fasteners, bracing, and ventilation systems also help regulate roof temperature and reduce the risk of refreezing. By reinforcing key areas and managing snow and ice buildup, steel buildings stay strong and secure through even the harshest winter conditions.

Fire - Fire wall assemblies enhance fire safety in steel buildings by compartmentalizing spaces and slowing the spread of flames. Builders design these assemblies to withstand high temperatures using fire-resistant materials like gypsum, cement board, or fire-rated steel panels. When integrated into the building’s layout, fire walls create protective barriers between sections, giving occupants more time to evacuate and reducing overall damage. They also shield key structural elements—like steel beams and columns—from direct heat that could weaken the frame. By placing fire walls strategically and using the right materials, steel buildings offer stronger fire resistance and improved safety.

Pests - Steel framed structures offer a strong advantage for pest control because it resists damage from termites, rodents, and other pests. Unlike wood, steel doesn’t serve as food or nesting material, making it an unappealing choice for infestations. It also won’t rot or decay—conditions that often attract pests to wooden structures. Steel framing makes inspections easier too, with fewer hidden spaces where pests can hide. By choosing steel, building owners reduce the risk of pest-related damage and create a safer, longer-lasting structure.

Seismic activity - With the use of foundation piers and advanced anchoring methods, steel buildings provide resilience against seismic activity, making them ideal for earthquake-prone areas. Concrete or steel piers distribute the building's weight evenly and provide a stable base that absorbs seismic forces. Anchoring methods, like base plates and anchor bolts, secure the steel frame to the foundation, allowing the structure to flex during seismic movements without losing stability. Steel framing offers superior durability and flexibility compared to wood, which can warp, rot, or decay over time. This combination of foundation piers, strong anchoring, and steel’s strength provides better earthquake resistance, ensuring long-term safety and sustainability in seismically active regions.

Did you know? Many insurance companies offer reduced premiums for steel buildings due to their performance in extreme weather conditions.

Myth #4: Engineered Steel Buildings Are Hard to Insulate and Uncomfortable Inside

The Truth: Not true at all. Modern insulation systems—such as insulated metal panels, vapor barriers, and spray foam—make steel framed buildings surprisingly energy-efficient. When installed correctly, they maintain indoor comfort just as well as (or better than) wood-framed structures.

Steel framed structures can achieve R30 or higher in insulation values, making them energy-efficient and well-suited for both temperature regulation and sustainability. This can be accomplished through advanced insulation systems integrated into the roof and wall assemblies.

Steel framed structures can achieve R30 or higher in insulation values, making them energy-efficient and well-suited for both temperature regulation and sustainability. This can be accomplished through advanced insulation systems integrated into the roof and wall assemblies.

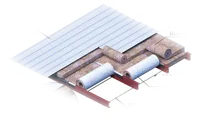

Roof & Wall System

In the roof, systems like spray foam insulation, rigid foam board, or batt insulation fit between steel framing to create a continuous thermal barrier, preventing heat transfer and boosting energy efficiency. In the walls, insulated metal panels (IMPs) or cavity wall systems with fiberglass or spray foam insulation provide a thick, continuous layer to achieve high R-values and minimize air leakage. These insulation methods enhance thermal performance, reduce heating and cooling costs, and ensure consistent indoor comfort. By incorporating advanced insulation in both the roof and walls, steel buildings easily meet or exceed R30 requirements, supporting environmental sustainability and long-term savings.

Plus, metal buildings can be fully outfitted with:

- HVAC systems

- High flow ceiling fans such as https://bigassfans.com/

- Skylights and windows for added airflow and natural light.

Whether you’re building a climate-controlled storage facility or a cozy workspace, steel structures are fully capable of meeting modern energy and comfort standards.

Myth #5: Steel framed buildings Are Cheap or Flimsy

The Truth:

Engineered steel buildings are cost-effective—not because they’re cheaply made, but because they minimize waste, reduce construction time, and require less maintenance over time. Pre-engineered steel systems are precisely manufactured, quality-tested, and engineered to meet strict building codes, resulting in a strong, secure structure built to last for decades. You’re not compromising quality—you’re just building smarter.

Not all steel buildings are created equal

One key difference is the gauge—or thickness—of the materials used. Some buildings use thinner, lower-gauge cladding and framing that may cost less upfront but lack durability. Thinner panels are more susceptible to denting, warping, and damage from harsh weather like hail, wind, and heavy snow.

On the other hand, higher-quality steel buildings use thicker materials—like 26 or 24-gauge cladding—which are more resilient, offering better structural strength, impact resistance, and longevity. While investing in thicker steel may come with a slightly higher initial cost, it pays off in long-term performance, reduced maintenance, and better protection for your investment.

Choosing higher-quality materials ensures your building endures the elements, retains its value, and continues performing for decades, making it a smart, cost-effective choice in the long run.

Final Thoughts

Don’t let outdated ideas keep you from considering a steel building for your next project. Whether you’re planning a storage facility, a commercial space, or a creative getaway, steel offers flexibility, strength, and style in one powerful package.

If you have questions about how a steel building might work for your business or property, we’d be happy to help. Reach out today for a quote or design consultation, and let Jones Roofing & Construction turn your vision into something strong, lasting, and uniquely yours.